FIBC Bags / PP Woven Bulk Bags / Jumbo Bags - (500-3,000kg)

Although it may seem like a 'bag is just a bag,' the truth is that there are a variety of factors to consider. What is the best gauge plastic to meet my required safety factor? What is the most suitable type of lifting loops? Can these bags be reused? Transport method, storing facilities, and logistics are just some of the variables that can have an impact when considering costs. Whatever the case may be, you can choose from our product line, or let our design and customer service team work with you to design and develop the perfect bag according to your unique specifications and needs. The following are some of our more widely used designs or you could also refer to our Customized Options for more information.

- Standard Design

- Baffle / Quadro Design

Standard Design

A basic square base with four lifting loops sewn across the corners of the bag is an economic construction for easy handling. The polypropylene fabric is designed to meet 5:1 safety factor. The standard PP woven bags are excellent for a variety of application and they are available in desired dimensional specifications.

Baffle / Quadro Design

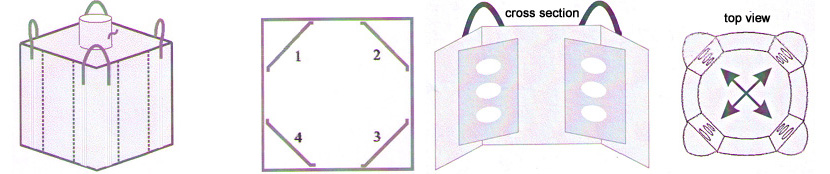

These bags are manufactured with in-built baffles which provide a distinguished look to the bag thereby helping in the transportation. The inner baffles maintain the original shape of the content packed in the bags. As a result, the content is kept square on the pallet and acquires less space in the warehouses. With heat cut holes on the internal supporting 4 panels, they help to maintain a cubic shape when flowing the materials into the corners during filling and discharging. Baffle / Quadro bags reduce the loading, stacking and warehousing space by up to 30%, giving you better space utilisation. They are stable and stackable, ideal for products with low bulk densities. These Q bags are available in desired dimensional specifications.

4 panels are stitched to the outer layer and keep the bag in shape